Planning and accurateness

Posted in 25/November/2015

Since September, Reframax has worked for Vale S.A. Pelletizing Plant, in São Luís, Brazilian State of Maranhão. It disassembles heavy equipment, such as Lattice Conveyor Belt, Roll Press, and Pelletizing Disk. There are about 664 tons of metal structures and equipment, 36 thousand meters of cables and conduits, and 310 parts such as transformers, pumps, motors and panels to be disabled and removed from the location.

The work involves lifting and moving equipment which weigh more than 40 tons and require extensive planning. “It is a service of high risk and requires a planning that contains every variable in details, in addition to quality and efficiency on maneuvers with large cranes, ensuring team safety and both client and Reframax properties,” says Edgardo Fiorella, Contract Coordinator.

The work involves lifting and moving equipment which weigh more than 40 tons and require extensive planning. “It is a service of high risk and requires a planning that contains every variable in details, in addition to quality and efficiency on maneuvers with large cranes, ensuring team safety and both client and Reframax properties,” says Edgardo Fiorella, Contract Coordinator.

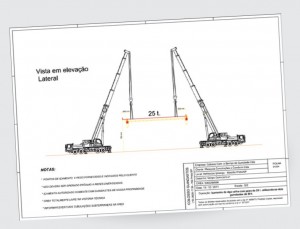

On Rigging Plans, we forecast the use of cranes that synchronically lift and move different parts, such as Span Ore Conveyors, which will be removed and placed on the floor to be disassembled later.

Rigging Plans

Calculate and integrate the variables that interfere on lifting cargo, such as crane position and power, position of parts, wind speed, among others.